Spray painting - High gloss paint

Spray painting: Using spray guns with air pressure to disperse into uniform and fine

droplets and

apply the painting to the surface of the object. Application: generally used in the

appearance of

smart hardware, home appliances, and plastic parts.

Learn

More

Spray

painting - Matt paint

Spray painting: Using spray guns with air pressure to disperse into uniform and fine

droplets and

apply the painting to the surface of the object. Application: generally used in the

appearance of

smart hardware, home appliances, and plastic parts.

Learn

More

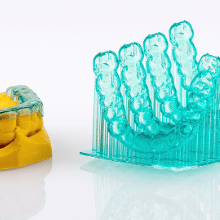

Vacuum plating - High gloss paint

Vacuum plating mainly includes vacuum evaporation, sputtering and ion plating. They

are

all used to

deposit various metal and non-metal films on the surface of plastic parts through

distillation or

sputtering under vacuum conditions. It can get very thin surface coating. Detail

sanding

would proceed

for these parts in order to achieve the best surface effect after plating.Features:

fast

speed and

good adhesion.

Application: functional coatings for higher-end products, household appliances, and

cosmetic

packaging.

Learn

More

Vacuum plating - Matt paint

Vacuum plating mainly includes vacuum evaporation, sputtering and ion plating. They

are

all used to

deposit various metal and non-metal films on the surface of plastic parts through

distillation or

sputtering under vacuum conditions. It can get very thin surface coating. Detail

sanding

would proceed

for these parts in order to achieve the best surface effect after plating.Features:

fast

speed and

good adhesion.

Application: functional coatings for higher-end products, household appliances, and

cosmetic

packaging.

Learn

More

#1000

sanding

Sanding is the use of fine abrasive sand particles to rub the surface of the product

to

produce a

diffuse, non-linear texture effect. Adhere different abrasive grit to the backing

paper

or the back of

the board, and the abrasive grit can be distinguished by different granularities

according to the

size: the higher the particle size, the finer the abrasive grit, so the surface

effect

is better.

Learn

More

Dyeing

Dyeing is done in a special solution containing dyes and particular chemical

material.

Dye molecules

are fixed to the fiber by absorption, diffusion, or bonding with temperature and

time

being key

controlling factors. Usually the result of dyeing will have a certain color

difference.

Learn

More

Silkscreen

Silkscreen generally refers to screen printing, which is the process of pressing ink

through a

stencilled mesh screen to create a printed design, graphics and text.

Kindly note that silkscreens can be made only on flat surfaces. ONLY Ai and svg

formats

are acceptable

and meanwhile mark the dimension and placement on the 2D technical drawings.

Learn

More

Laser

engraving

Laser engraving is the use of laser technology to engrave text and pattern on

objects.

The characters

engraved by this technology have no nicks, the surface of the object is smooth, and

the

text and

pattern will not wear out.

Kindly note that laser engraving can be made only on flat surfaces. ONLY Ai and svg

formats are

acceptable and meanwhile mark the dimension and placement on the 2D technical

drawings.

Learn

More