Silhouette_:

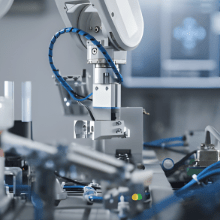

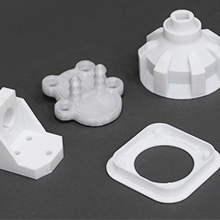

CNC machining and 3D printing have a wide range of applications in the healthcare industry. In terms of CNC machining, it is used for manufacturing medical instruments and equipment components with high precision, ensuring accuracy and reliability. It is also employed in the production of implants, such as artificial joints, bone plates, and screws, allowing for precise cutting and shaping of metal and alloy materials to meet personalized implant requirements. CNC machining is further utilized for rapid prototyping of medical devices, enabling design validation, functional testing, and iterative improvements. Additionally, it facilitates customized production of medical instruments and devices, including prosthetics and orthopedic appliances, tailored to individual patient needs.

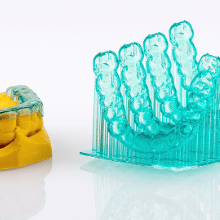

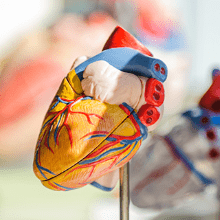

As for 3D printing, it finds applications in the rapid prototyping of medical instruments and devices, accelerating product development and refinement processes. It is particularly suitable for the production of customized implants, where it allows for the creation of personalized implants based on patients' anatomical structures and requirements, such as artificial joints, dental implants, and prosthetics. Furthermore, 3D printing technology is used to manufacture highly realistic medical models, utilized for surgical simulations, medical education, and training, enhancing the skills and knowledge of healthcare professionals. It also enables the production of medical aids like orthotics, supports, and transparent aligners.

Silhouette_:

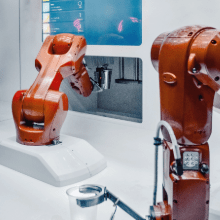

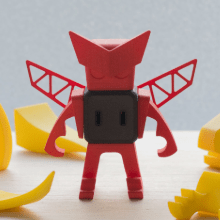

3D printing has several applications in the robotics industry. It can be used to quickly prototype and model robots to verify design and functionality. In addition, 3D printing can also manufacture robot parts with complex shapes, such as lightweight structures and hollow structures, to improve the performance and efficiency of robots. 3D printing also supports personalized customization, which can manufacture robot components and shells according to specific needs.

Silhouette_:

3D printing has numerous innovative applications in the robotics industry. It can be used to manufacture robot exoskeletons, providing rehabilitation, mobility assistance, and human-robot collaboration. Custom-made exoskeleton structures, lightweight and comfortable, can be created using 3D printing technology, tailored to individual dimensions and requirements.

Furthermore, 3D printing enables the production of flexible and elastic robot components such as sensors, joints, and grippers. These components enhance the adaptability and operational capabilities of robots in complex environments. The flexibility of 3D printing also allows for the manufacturing of intricate structures and internal channels, offering design flexibility and integration of functionalities.

Another innovative application is the ability to combine multiple materials within a single printed component. In the robotics field, this means incorporating different properties and functions, such as hardness, elasticity, and conductivity, into a single part. This opens up opportunities for multifunctional and multitasking operations of robots.

Additionally, 3D printing facilitates rapid prototyping and customized development in the robotics industry. It accelerates the production of robot prototypes and customized parts, speeding up the product development and testing processes. Designers and researchers can iterate and optimize designs more quickly, meeting specific application needs.

Wearable robotics is another area where 3D printing shines. It enables the manufacturing of lightweight and ergonomic wearable robot components. Through 3D printing, personalized wearable robot parts can be custom-made to fit individual body structures and movements, providing functions such as human augmentation, walking assistance, and rehabilitation training.

These innovative applications of 3D printing showcase its potential in the robotics industry, offering design flexibility, performance optimization, and personalized applications. As technology continues to advance, we can expect more exciting and groundbreaking applications to emerge.