Prototipos de PCB de forma sencilla

Servicio completo para prototipos de PCB personalizados.

9:00 - 18:00, Mon.- Fri. (GMT+8)

9:00 - 12:00, Sat. (GMT+8)

(Excepto los días festivos chinos públicos)

Prototipos de PCB de forma sencilla

Servicio completo para prototipos de PCB personalizados.

9:00 - 18:00, Mon.- Fri. (GMT+8)

9:00 - 12:00, Sat. (GMT+8)

(Excepto los días festivos chinos públicos)

PCBWay is definitely your trusted PCB & PCBA & CNC | 3D Printing partner! In addition to friendly service and on-time delivery, we also focus on producing high-quality products that meet or exceed customers’ expectations.

We have implemented the ISO9001 quality system. Quality control has always been an important part of our production process and runs through every link.

Our technicians have many years of experience, and have been working strictly in accordance with high requirements and standards.

READ MOREWe believe that only a complete quality control process is an effective means to ensure quality.

READ MOREWe can provide you with complete quality reports and common certifications as proof of the quality of our products.

READ MORE

The specifications of the raw materials

used in our production are available for download.

Our experienced technicians will always ensure that all products are of exceptional quality,

reliability

and consistency.

PCB Production standards follow IPC Class 2,IPC Class 3, ,Automotive Standard, Customer Standard

| Item | Advanced PCB | Standard PCB |

|---|---|---|

| Engineering |

one file/1 days+

Senior engineer |

mid-level engineer

(1 files/hours) |

|

Material

|

Shengyi,Rogers,Arlon,Isola, Omega,Nelco,3M etc.Meet IPC4101 class B/L | KB(kingboard)/GDM(goldenmax) Meet IPC4101 class B/L |

|

Ink,Soldermasks

|

Rohm&Haas,TAIYO,Kuangshun,Meet IPC-SM-840 class T | TAIYO,Kuangshun,Meet IPC-SM-840 class T |

| Drilling | Min Mechanical Hole Size 0.15mm,Laser hole 0.1mm | Min Mechanical Hole Size 0.2mm |

| Plating | PTH (Hole copper thickness≥20um),IPC 3(25um) | PTH(Hole copper thickness≥18um) |

| Soldermask offset | ±2mil | ±3mil |

| Dimensional deviation | ±0.13mm | ±0.2mm |

| Warping angle | 0.75% | 1% |

| Test method | A.O.I,Kelvin Four-terminal sensing,Microsection Inspection,Solderability Test,Impedance Test... | A.O.I.,Fly Probe Testing, E-test fixture |

| Glass transition ℃ | >140℃ | >130℃ |

| Etched line | Forbid to repair tracks(IPC 3,Automotive,Customer Standard) | - |

| Cleanliness | Cleanliness requirements beyond those of IPC | Cleanliness requirements beyond those of IPC |

The perfect quality assurance system and various testing equipment help us monitor the entire production process to ensure the stability of the process and product quality. At the same time, we also introduce advanced instruments and technical methods to achieve continuous improvement.

For each order submitted, Gerber files will be reviewed by our professional engineers before being sent to production. Engineers will confirm the production feasibility in terms of tolerance constraints such as board edge clearance, drilling, pad spacing, impedance and routing. When the engineer finds a problem with the file or there is something that can be optimized, an EQ will be raised, and our customer service representative will get in touch with you, so as not to delay production.

The quality of the raw materials determines durability of the finished products. Ensuring the high quality of raw materials is one of the most basic principles for PCBWay to manufacture products. PCBWay has been working with leading suppliers in the industry,and inspect materials according to international standards and customer requirements, such as Shengyi, Rogers, KB (kingboard) sheet, Rohm&Haas, TAIYO high-performance solder mask ink.

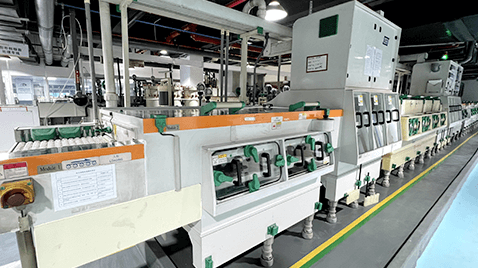

Click to view raw materialsIn order to ensure the best quality and reliability of PCB products, PCBWay continuously introduces advanced equipment, including but not limited to the following:

We strictly comply with ISO9001:2015 requirements and all production processes are in

line with IPC standards. In addition to basic visual inspections, all boards undergo the

most rigorous electrical tests. We use industry-renowned testing and inspection

equipment such as Flying Probe Testing, AOI (Automated Optical Inspection) and Copper

Thickness Tester.

We guarantee that every PCB in your hand is in good condition and you can proceed to the

next step of assembly safely. Various types of

test

reports

are available upon request.

Our quality control systems are regularly audited and assessed to ensure their compliance and effectiveness. A complete quality control system and 100% PCB testing procedures will ensure that every order you entrust is completed perfectly.

PCBWay has dozens of SMT production lines. Advanced production equipment, strict quality control and intelligent service system to ensure the standardization and best quality of each production process.

|

Production process and description

|

Production process and description

|

|---|---|

01-Process reviewAssess and inspect the particularity of the PCBA manufacturing process in advance, guide the production, and improve the quality from the process technology. |

02-IQC Incoming Quality Control

● Check whether the resistance and capacitance values are correct |

03-SPI Solder Paste InspectionSPI can detect whether the solder paste is sufficient and uniform, which can effectively prevent production quality problems in advance caused by poor solder paste printing. |

04-Online AOI InspectionThe AOI can detect the wrong solder, reverse solder, false solder, empty solder, incomplete solder, short circuit, offset, tombstone, etc. after reflow soldering. And it can also detect excessive solder, less solder, continuous solder and other undesirable phenomena in the appearance of PCBA solder joints. |

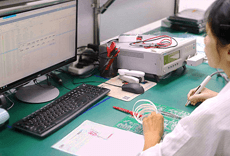

05-First sample testCombined with Gerber, BOM and coordinate files, the resistance and capacitance in the completed PCBA are verified again by the first-sample tester to ensure the correctness of all parameter values. |

06-Off-line AOI inspectionAccording to the IPC610D standard, inspect the soldered surface mount PCBA for errors, omissions, and false connections. |

07-X-Ray welding inspectionInspect the solder joints of invisible components to ensure the reliability of each solder ball of the BGA. |

08-QC manual inspectionRefers to the standard IPC--610 inspection standard, and the finished board is visually inspected to ensure 100 % Good products shipped. |

Before the production, our engineering team conducts a technical evaluation of your part design. This includes an assessment of important factors such as 3D and 2D drawings, material, surface finish, structure, workmanship and etc. When the engineer finds that there is a problem with the file or there is something that can be optimized, communicate with the customer in time to eliminate the problem before processing.

PCBWay strictly controls material and surface treatment suppliers, using high-quality materials to produce parts. Upon customer request, we provide certification of the materials used to manufacture your parts. Reports come from raw material manufacturers and usually include: material model number, material grades, material dimensions, mechanical properties, chemical analysis, etc.

Click to view raw materialsTo guarantee our strict quality control, we have the highest specification production workshop and the most advanced equipment, including but not limited to the following:

We strictly comply with ISO9001:2015 requirements. The parts will be processed in strict accordance with the established technological process. After the FAI report is passed, the mass production can be carried out. There is IPQC in the production process to ensure that every process is correct.

We have a dedicated QC team that 100% inspects finished parts before delivery, ensuring the parts we manufacture are of the highest quality. For all orders, we provide inspection reports upon request. The report will include the following: Number of parts, critical dimensions, threads and tolerances, thickness and depth, part appearance, and more.

Our quality control systems are regularly audited and assessed to ensure their compliance and effectiveness. A complete quality control system and the most stringent testing methods will ensure that we provide you with quality parts that meet your requirements.

To ensure that all orders are completed in accordance with the PCBWay Manufacturing Standards.

We can provide a complete quality inspection reports according to your requirements, including but not

limited to:

Thanks to the materials used and advanced technology, we always ensure highest quality of our

printed circuit boards!

PCBWay can provide customers with certifications in various markets, such as: EU RoHS certification,

EU CE certification, US UL certification, US FCC certification, Australia SAA certification,

Australia C-tick certification, Australia RCM certification, Japan PSE certification, Brazil INMETRO

certification, Mexico NOM certification, Canadian IC certification, Korea lithium battery KC

certification, Argentina IRAM S-mark certification, DLC certification, GS certification, CB

certification, etc.

If your order does not meet specifications, you will enjoy our rework or refund policy.

You can issue any complaint within 5 working days after receiving the products. Our after-sales service

team will resolve these issues as soon as possible, usually within 1-3 working days. We promise that if

quality problems are caused by fabrication, PCBWay will be responsible for free maintenance or rework,

and bear the return shipping costs.

We use the following raw materials in our production.

The following 60+ product specifications are available for download:

The quality and service of PCBWay have been trusted by many customers, platforms and well-known

bloggers,

and have reached a long-term cooperative relationship with them. Discover our customers'

testimonials.

We wanted to thank PCBWay for the quality of our exchanges and for the trust they place in Siemens. PCBWay becomes one of our partner for our new project development. Our new strategy project allows us to make a big step toward large scale IOT solutions and this could not be done without the support of PCBWay. This is a mutual commitment and we believe in PCBWay to advise us, guide us and share knowledge in order to create a true collaborative partnership.

PCBWay and Samsung have collaborated for several years in the design and manufacturing of PCB(s). PCBWay's expertise in technology development and manufacturing complements Samsung's 20-year experience in the development, sales, marketing and Cusomer Service in PCB projects, continuously strengthening their leading position in the international markets.

PCBWay have been a very good supplier to Midea for PCB(s). They are extremely competitive in pricing with on time delivery. We have great support from their customer service personnel, very fast with responses and able to assist in almost every occasion.

I am fond of creating visually challenging, out-of-the-ordinary, and unique PCB designs for my projects. Over the years, PCBWay has never ceased to amaze me with its high-quality service, advanced manufacturing options, and acceptance of creativity.

PCB Way and Ipesi Magazine maintain the partnership for a few years, with an excellent relationship. The technical capacity and service they offer to partners are at the highest level. Without a doubt, we recommend it to the market.

Hundreds of SnapEDA's users rely on PCBWay each month to manufacture their boards because of their high-quality services. Their speed and reasonable cost make them a preferred choice among our community - SnapEDA

Makers in the Raspberry Pi community are increasingly inclined to

use PCBWay to

complete their ideas.

We have been working with PCBWay for over a year and love the relationship.

Their

team is very professional, responsive and friendly.