Prototipos de PCB de forma sencilla

Servicio completo para prototipos de PCB personalizados.

Centro de Ayuda

Líneas directas de servicio

+86 571 8503 9969

9:00 - 18:00, Mon.- Fri. (GMT+8)

9:00 - 12:00, Sat. (GMT+8)

(Excepto los días festivos chinos públicos)

ES / USD

Bienvenido a PCBWay

- ¿Cliente nuevo?

- Regístrate gratis

Inicio

Cotización instantánea

CNC | Impresión 3d

Montaje de PCBs

Diseño de PCB

OEM

Producto y capacidades

¿Porqué?

Opiniones

Proyectos Compartidos

Tienda

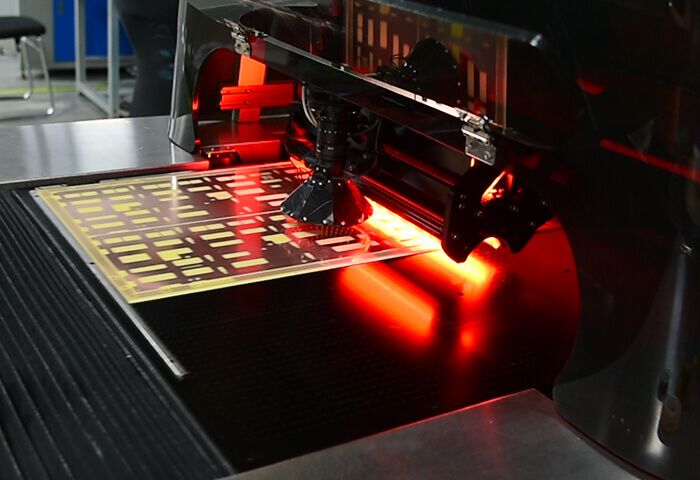

Printed Circuit Boards

- PCB Capabilities

- Advanced PCB

- Advanced PCB Capabilities

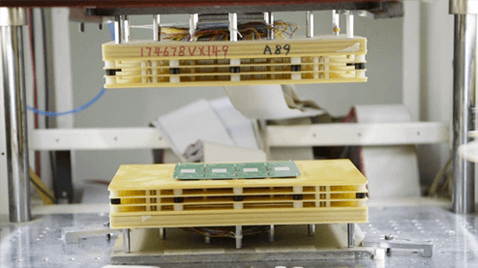

- PCB Prototype

- Flex and Rigid-Flex PCBs

- Flexible PCBs

- Rigid-Flex PCBs

- Aluminum PCB

- Metal core PCBs

- High Frequency PCBs

- High-TG PCBs

- Thick-Copper PCBs

- HDI PCB

- LED PCB

- Quick turn PCB Fabrication

- PCB Prototyping

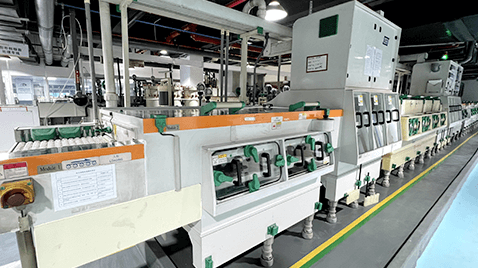

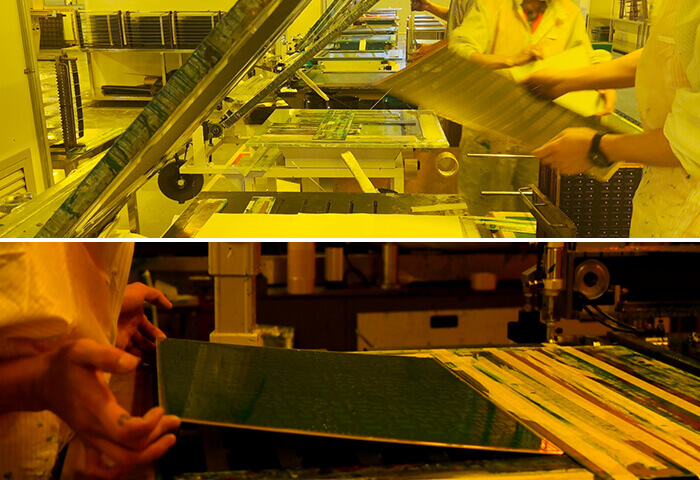

- PCB Production Process

- PCB Products

- PCB Engineering Questions

- FAQ of PCB

SMD-Stencils

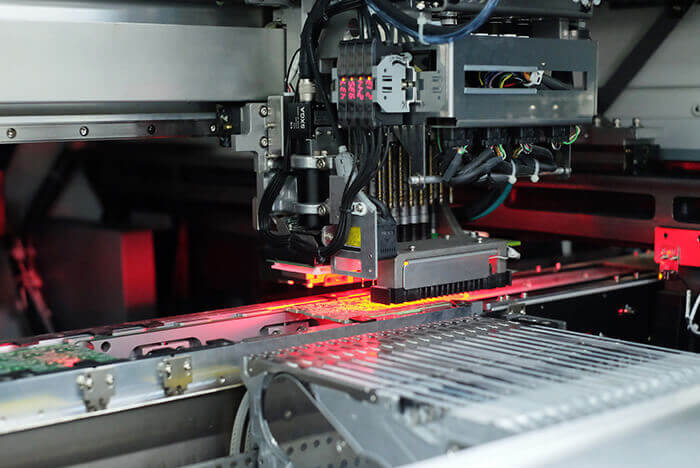

PCB Assembly

- PCB Assembly Overview

- PCB Assembly Capability

- SMT Ordering Necessary Files & Info

- SMT Assembly Capabilities

- Mixed Assembly Advantages

- Through-Hole Assembly

- BGA Assembly Capabilities

- Components Sourcing

- Panel Requirements for Assembly

- Special Reminders

- File Requirements

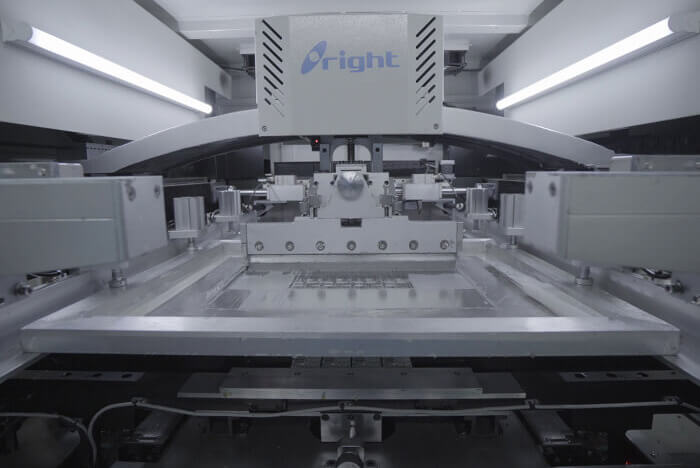

- Production Process

- PCB Assembly Products

- PCB Assembly FAQ

PCB Design-Aid & Layout

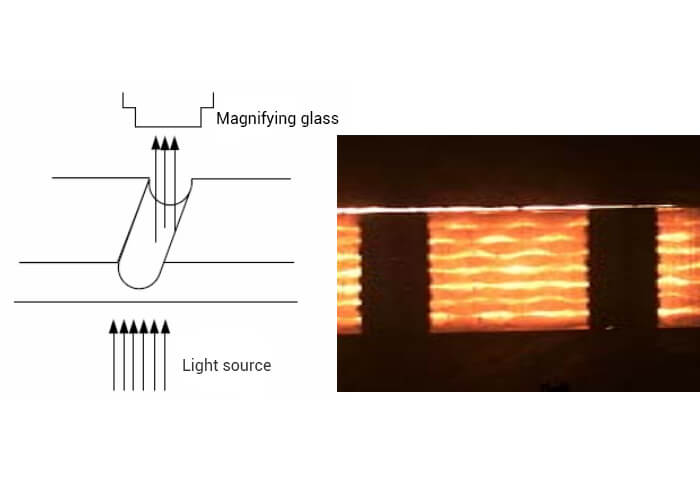

Drills & Throughplating

Layer buildup

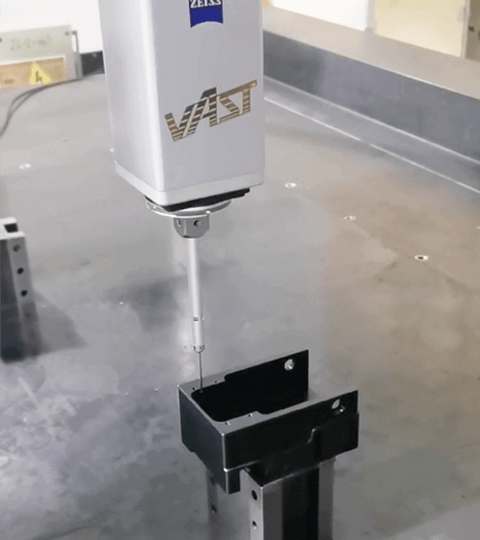

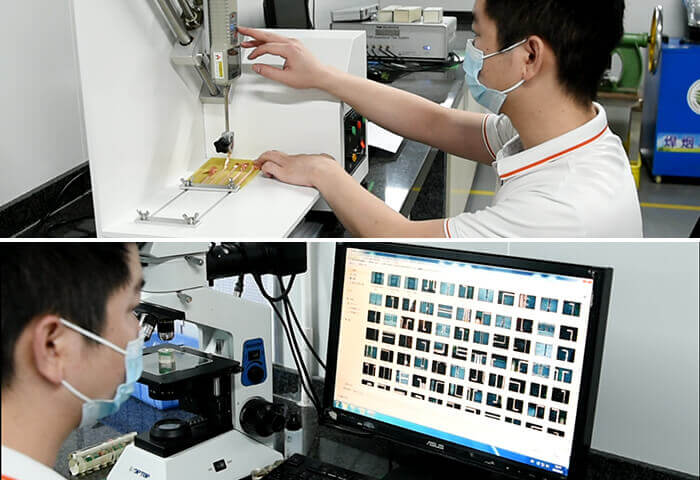

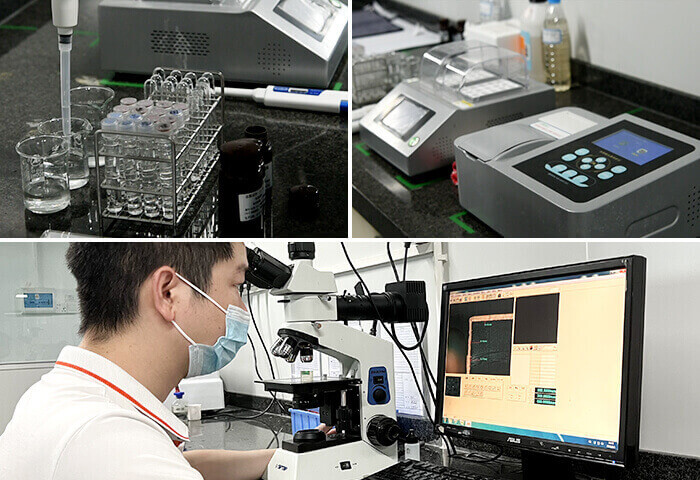

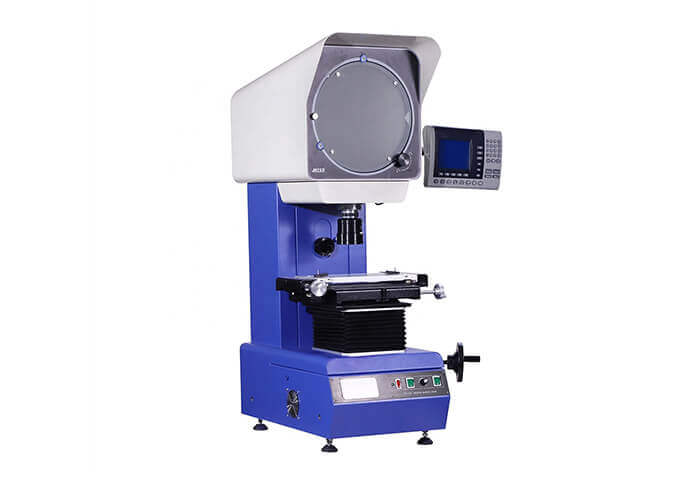

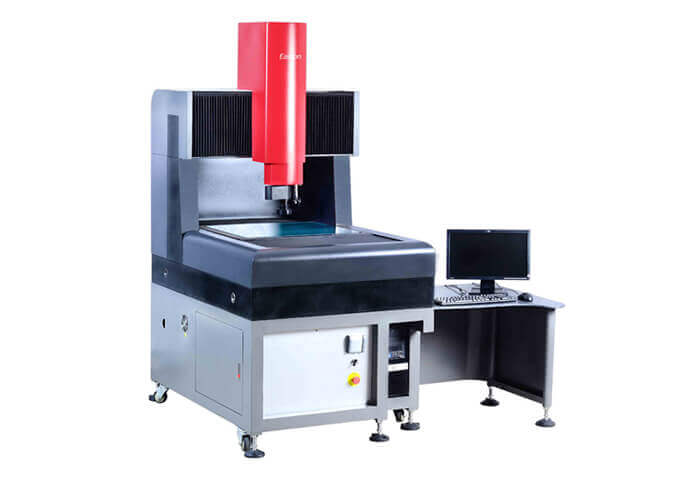

Quality

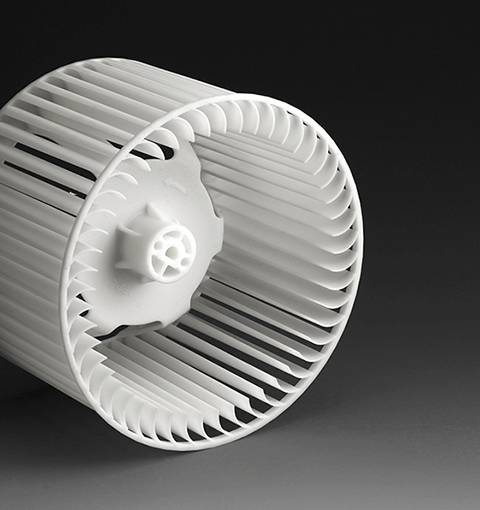

CNC Machining

Sheet Metal Fabrication

Additional Services